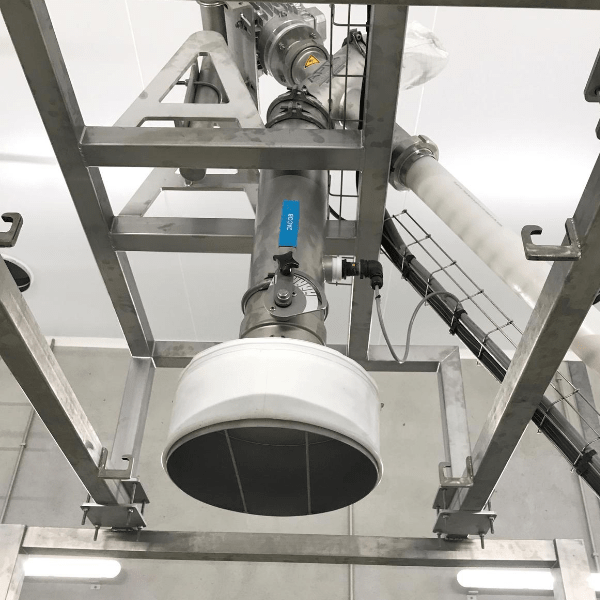

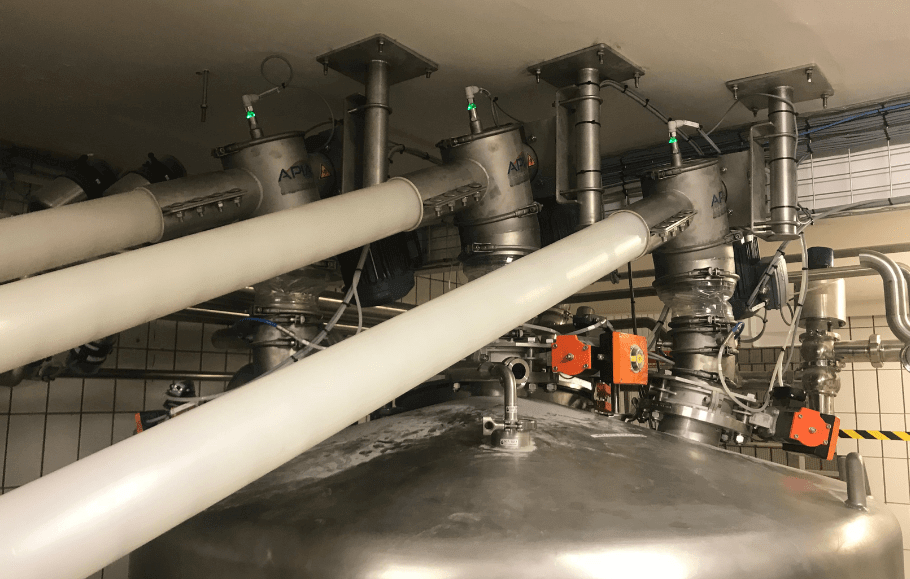

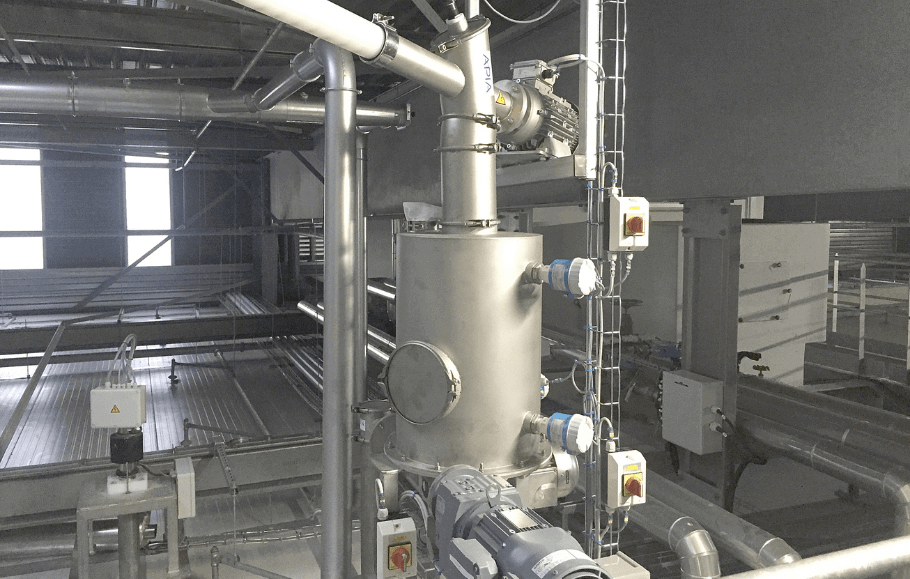

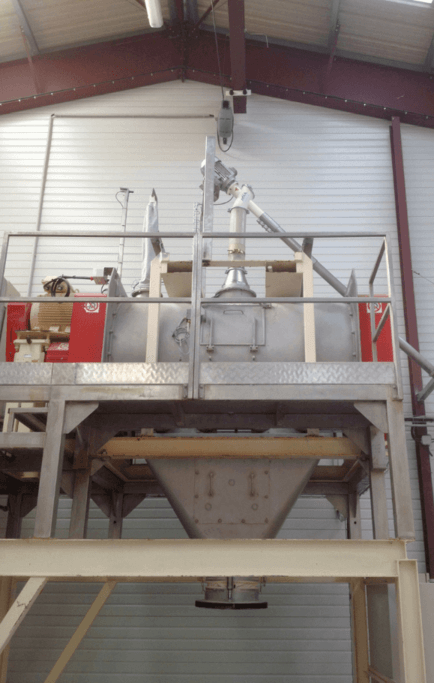

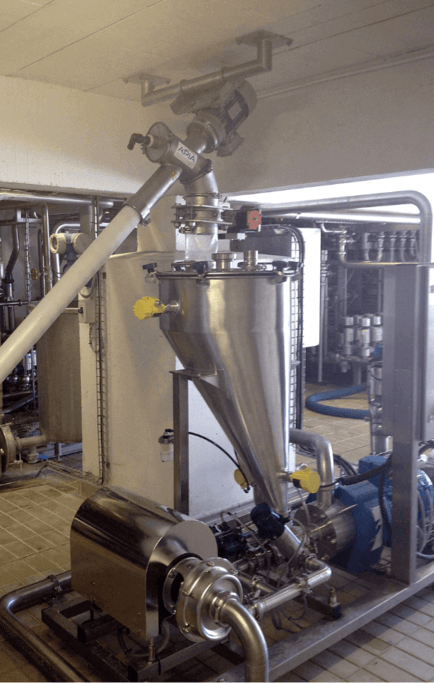

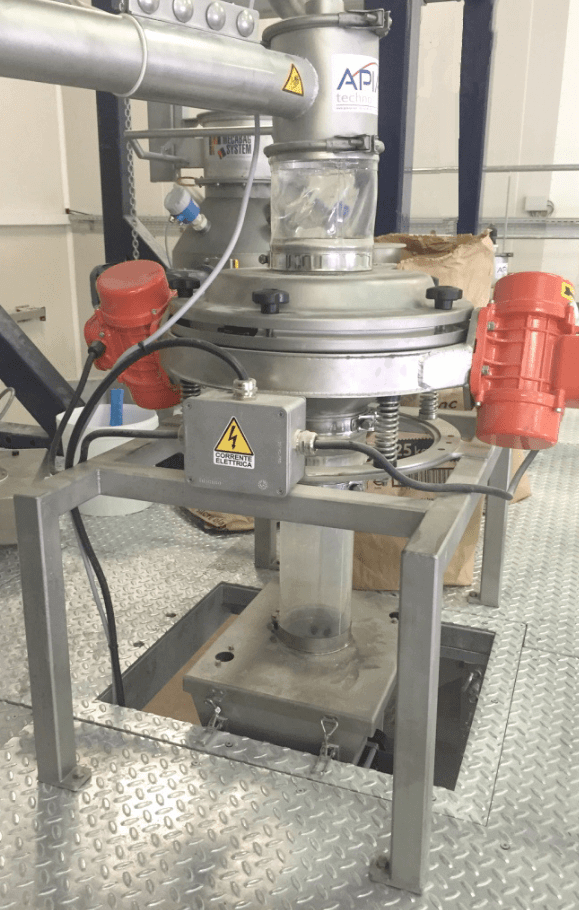

Transfer and dosing of powders for the food industry

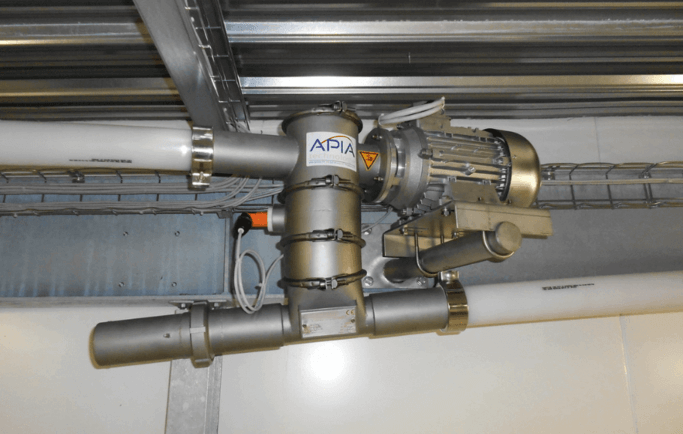

APIA Technologie designs and builds installations dedicated to the handling of dry bulk products and the dosing of powder ingredients. Every day, our teams support projects optimising the industrial processes of agri-food plants.

What are your needs?

Products

Solutions

Articles / Case Studies

Our services

Discover our services

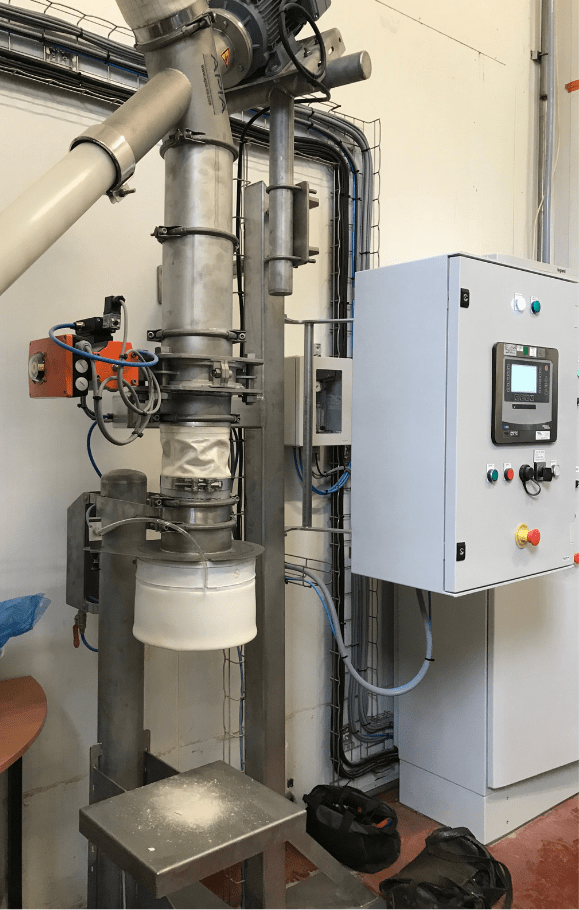

From design to the monitoring of your powder installations

Apia Technologie offers end-to-end bespoke solutions to address your priority concerns: productivity, compliance with food standards, ATEX safety audits. From needs analysis right through to commissioning, you will have a dedicated contact throughout your project.

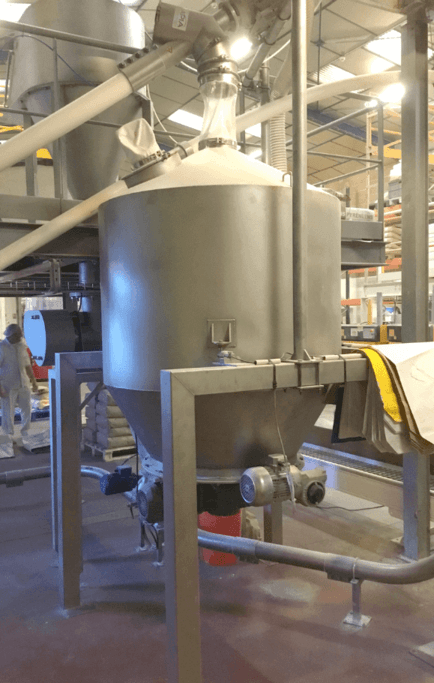

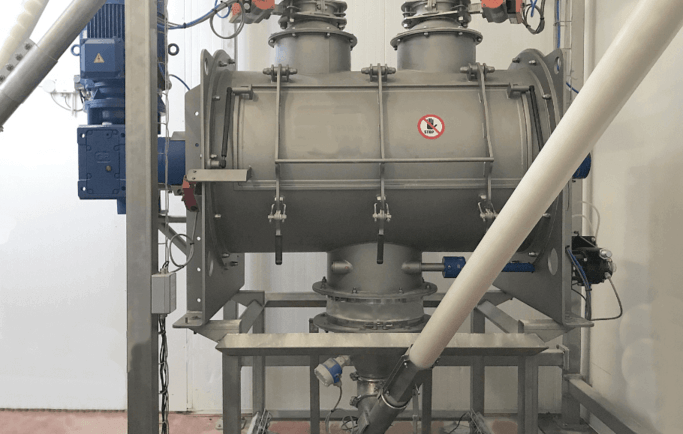

Powder handling for all sectors of the food industry

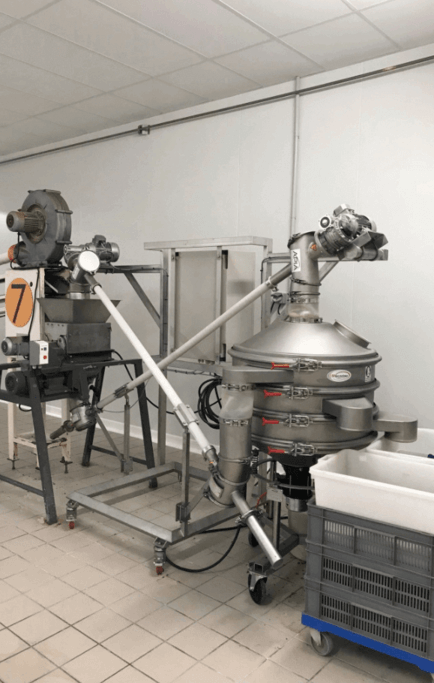

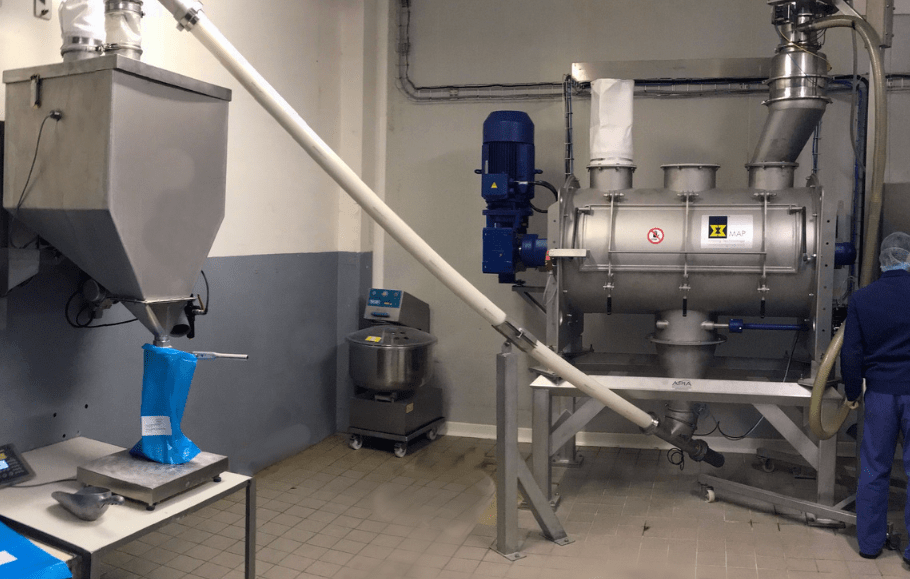

Optimisation of the powder circuit is always a cost-effective exercise provided your process is considered in its entirety. On a daily basis, our solutions demonstrate their efficiency in terms of health, operator safety, productivity and flexibility.

Feeding solutions

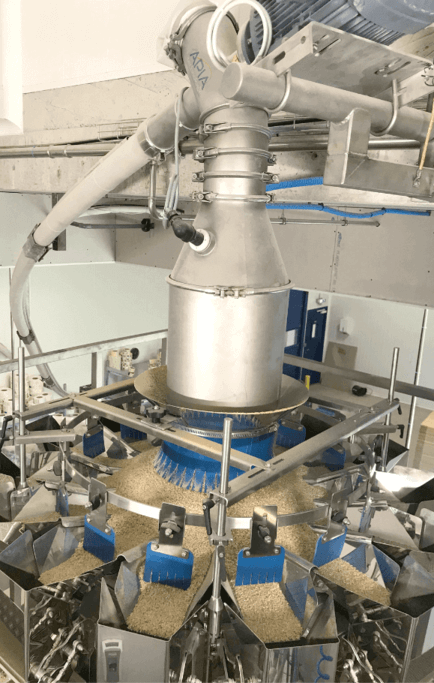

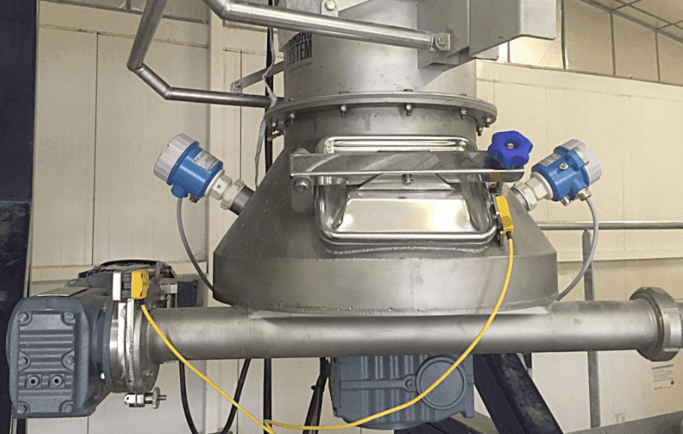

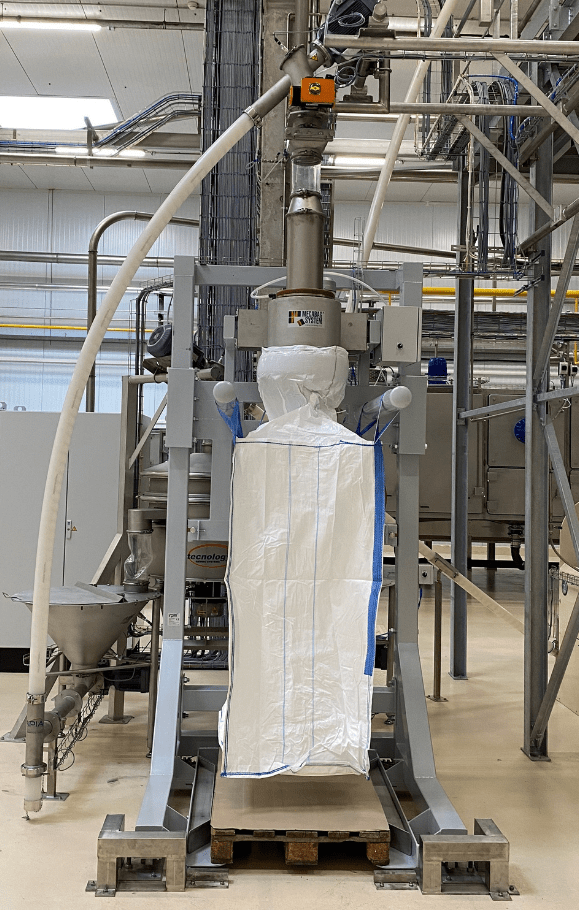

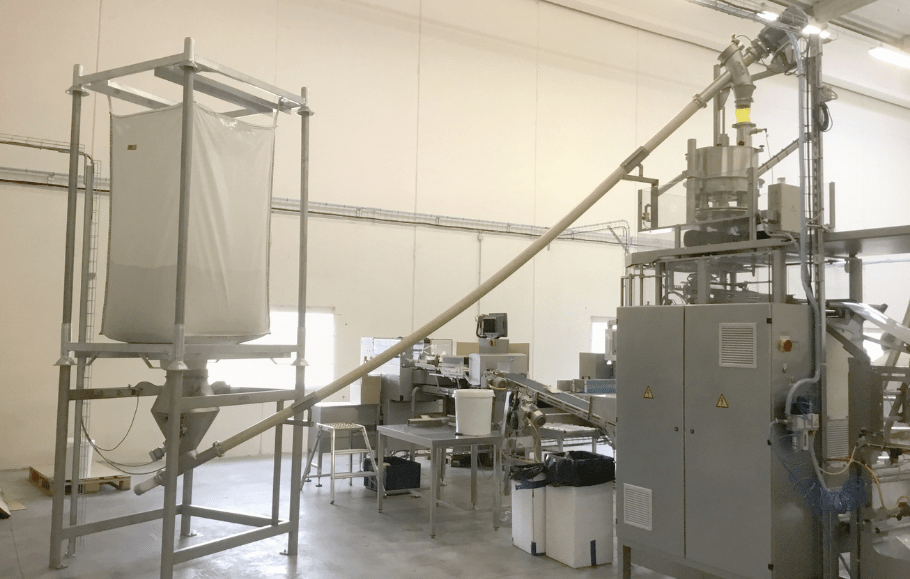

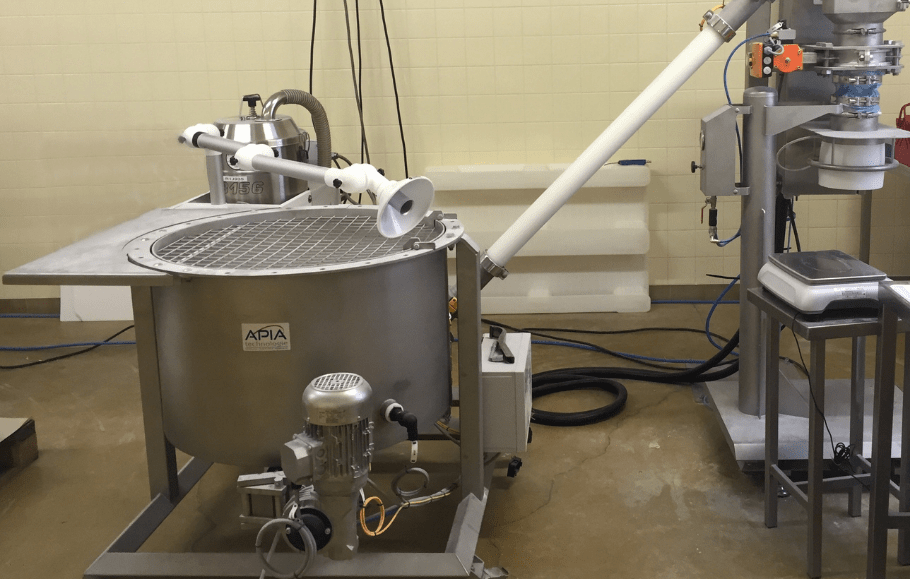

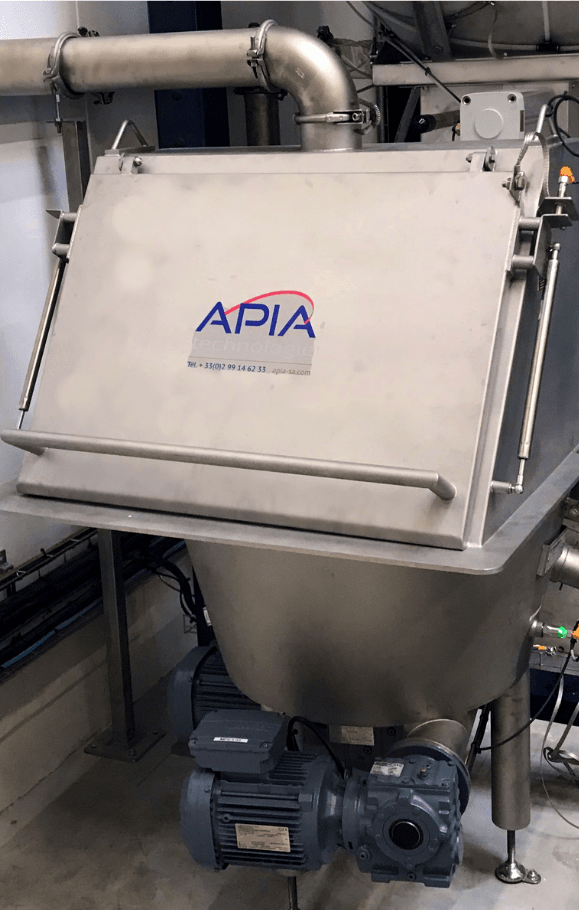

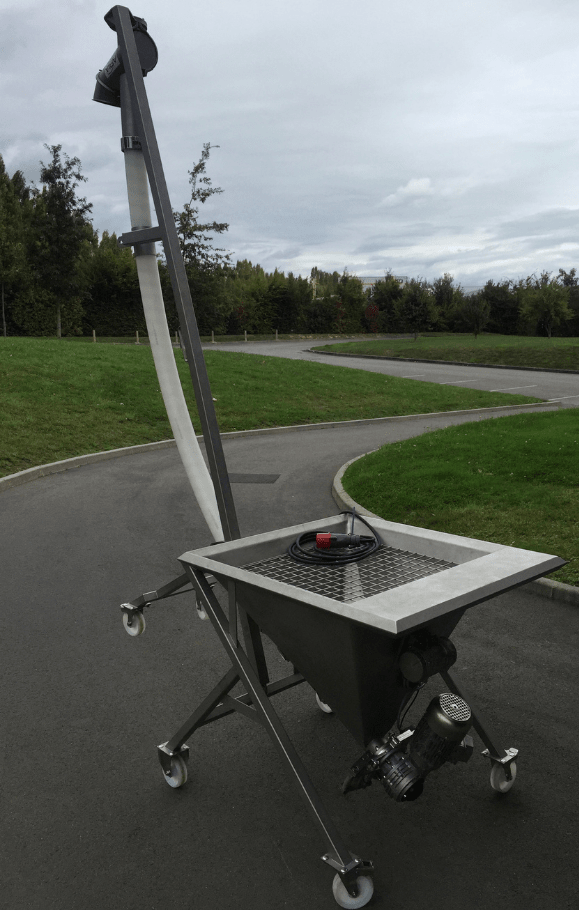

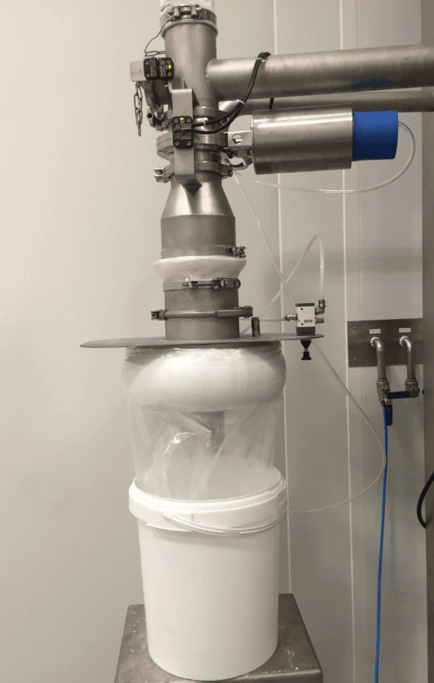

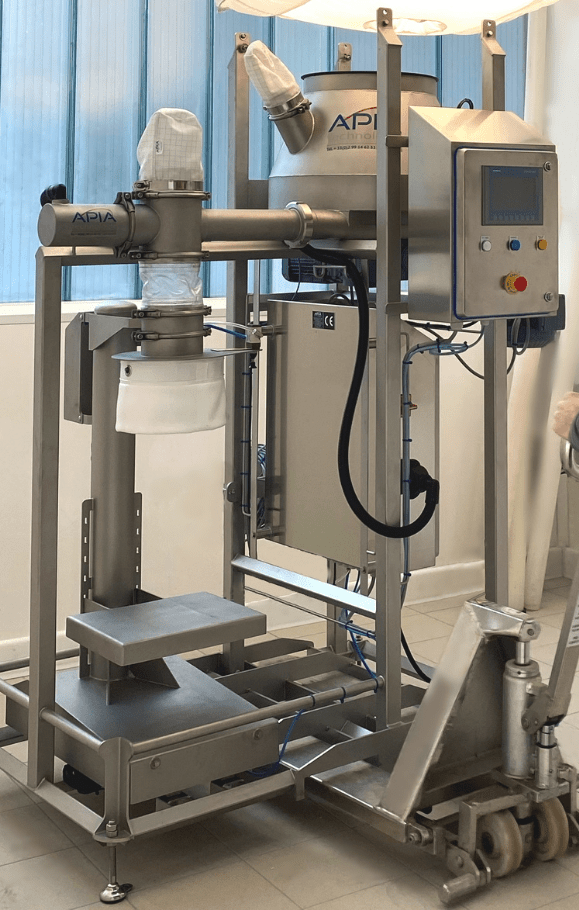

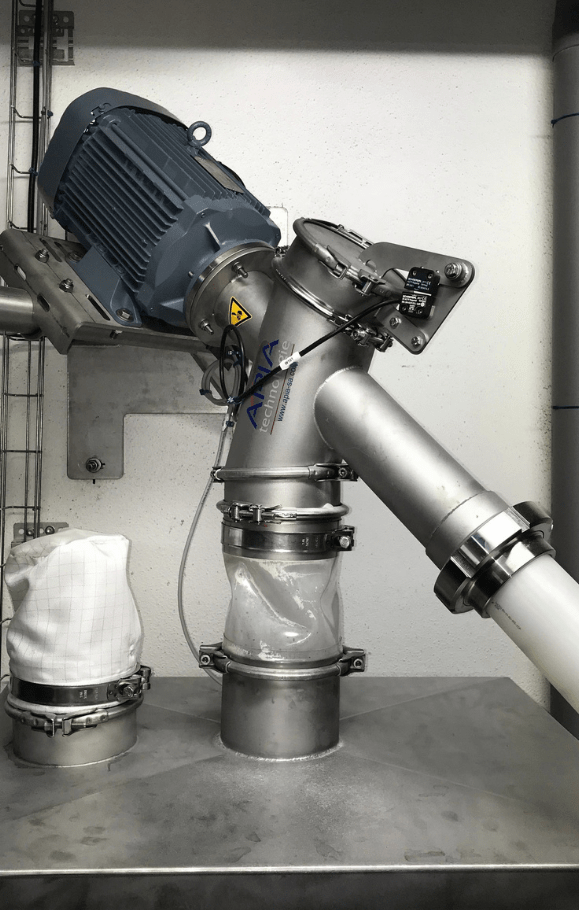

Reliable, hygienic and safe solutions for the transfer and dosing of ingredients

Apia Technologie is a designer, manufacturer and assembler. We deliver complete lines, sub-assemblies, stand-alone machines and accessories designed to manage the supply of dry products in your food workshops.

Transferring

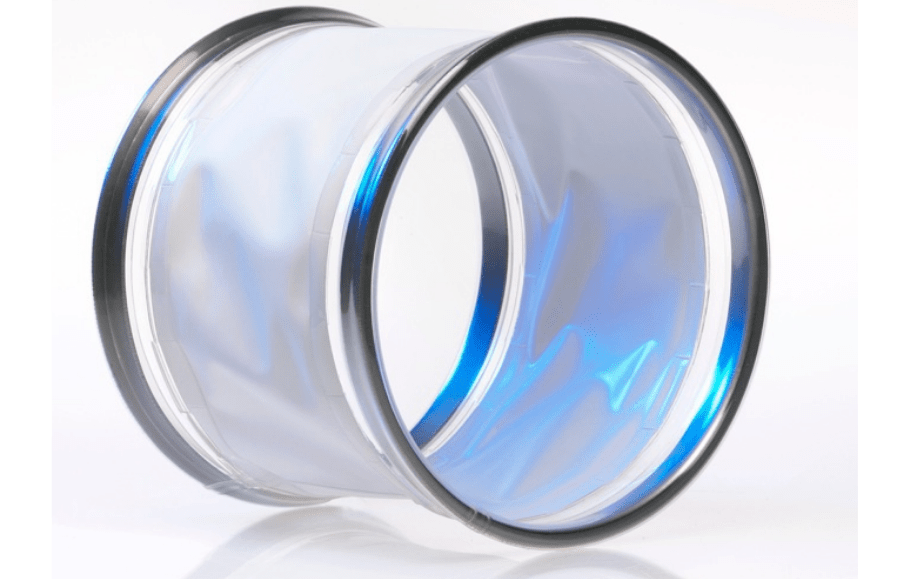

Options and accessories

Our know-how

Download the brochure

28 years serving agri-food plants

It is thanks to our activity since 1993 – delivering thousands of powder and granule conveying installations exclusively in the food industry – that we are able to adapt to the problems specific to each individual sector, taking a proactive approach and boosting the profitability of your workshops.

0

installations still in service

0

%

dedicated to the food industry

0

years

of presence in the agri-food industry

0

/year

Site visits

Why not you?

Join the hundreds of industrial operators who have benefited from our flexible, high-performance and robust technology. Let’s review your needs!

Latest blog articles

View all articles

Our processes

Our news

© Copyright 2025 APIA technologie