- Accueil

- Nos produits

- Ensemble de transfert T11

- Ensemble de transfert T12

- Ensemble de transfert T14

- Ensemble de distribution T51

- Ensemble de distribution T54

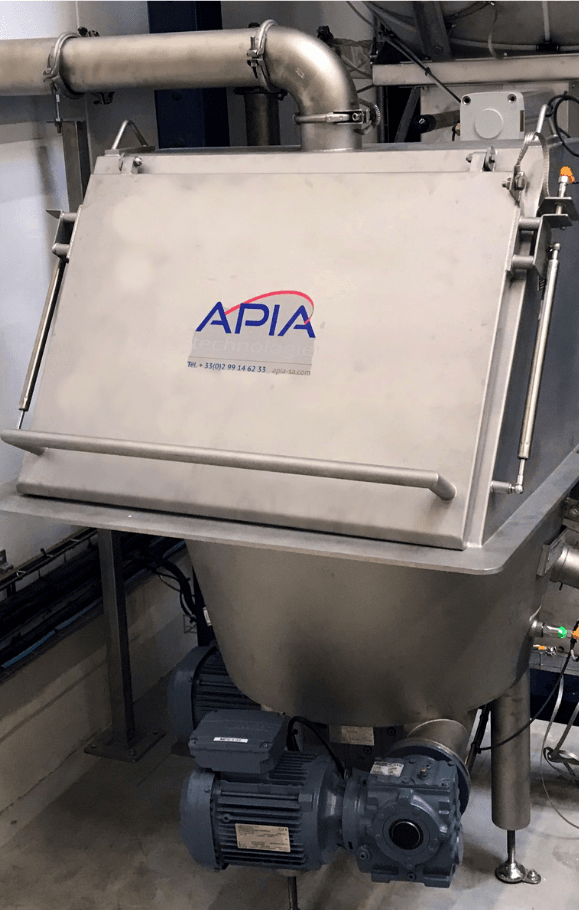

- Trémies pesées et trémies tampons

- Stations de vidange big bag

- Trémies vide-sacs

- Hottes de dépoussiérage

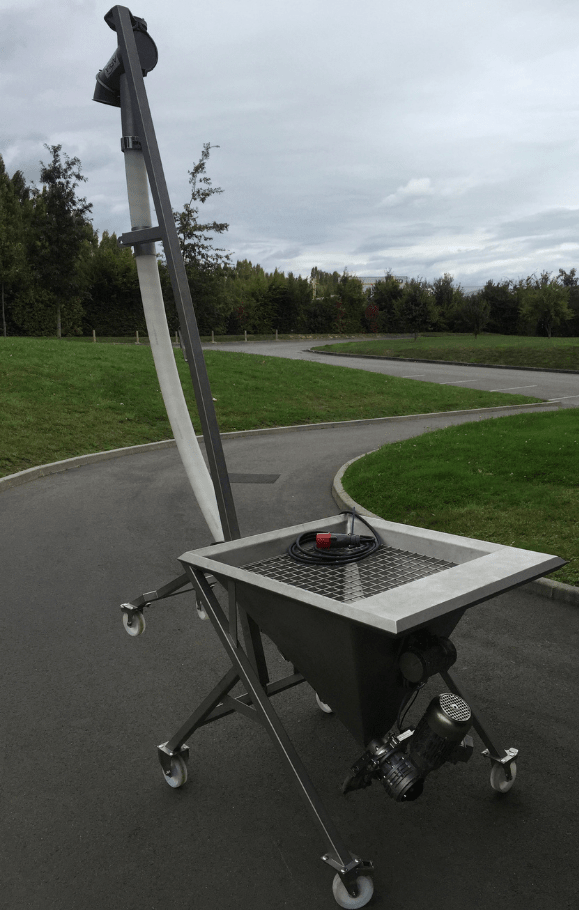

- Ensemble Mobile et Basculant (EMB)

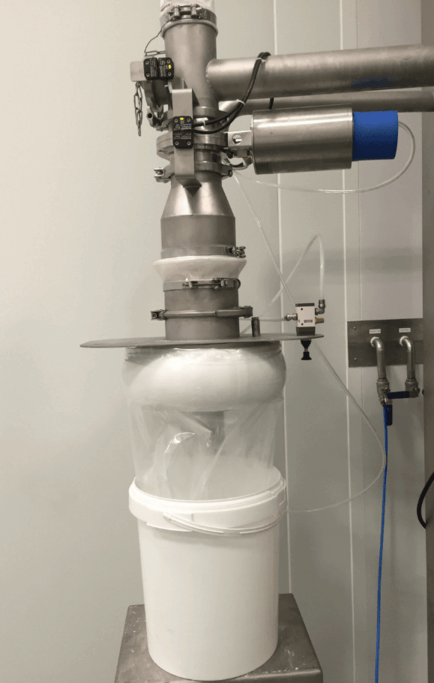

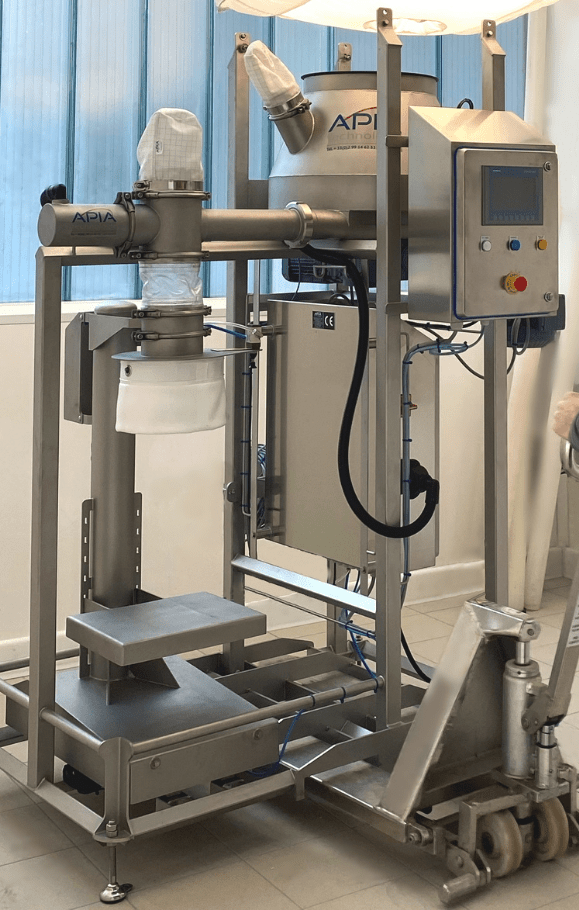

- Ensacheuse Peseuse Confinée (EPC)

- Ensacheuse Peseuse Mobile (EPM)

- Options de vidange et démontage rapides

- Conduits et vannes

- Manchettes de connexion

- Passe Cloisons

- Nos Solutions

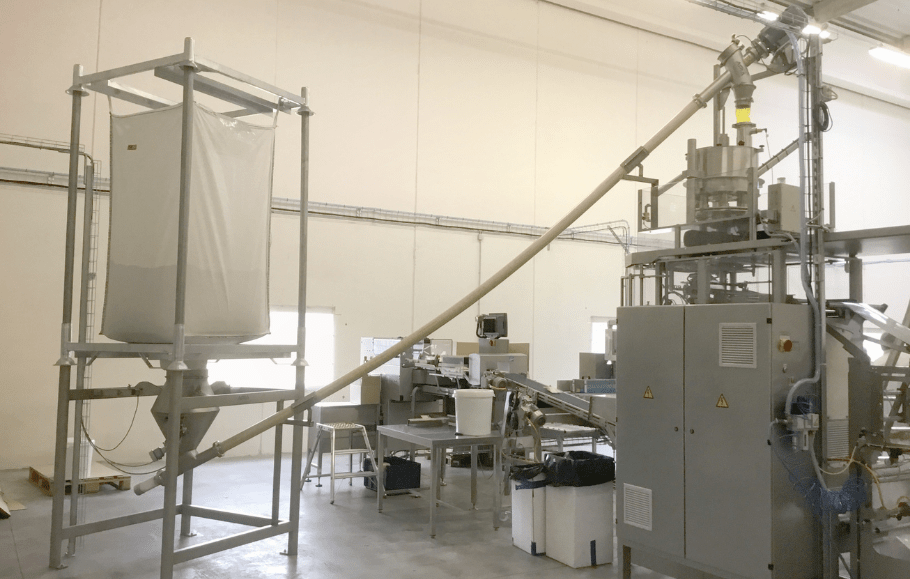

- Alimenter un Big Bag

- Alimenter une Ensacheuse

- Alimenter une Conditionneuse

- Alimenter des silos et trémies tampons

- Alimenter une Trémie pesée

- Alimenter un Doseur

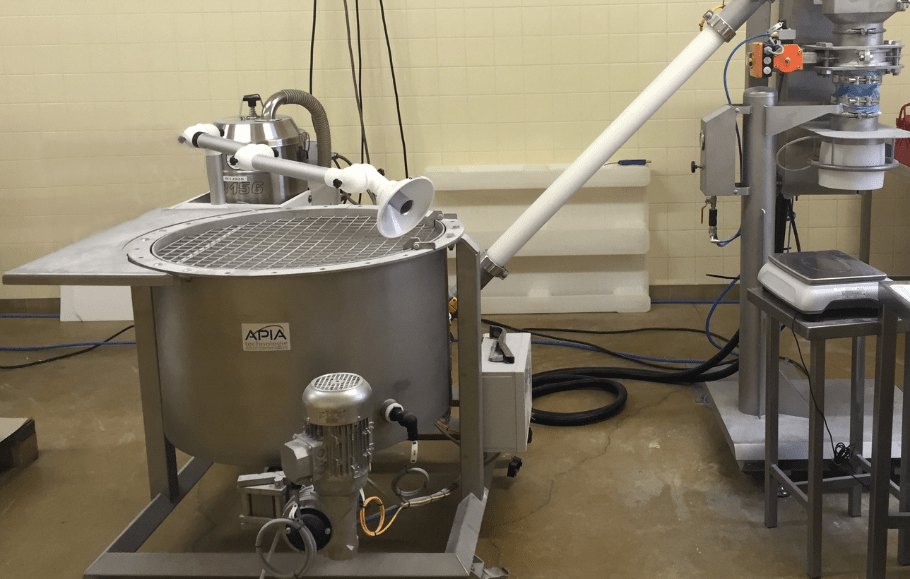

- Alimenter un Mélangeur Poudres-Liquides

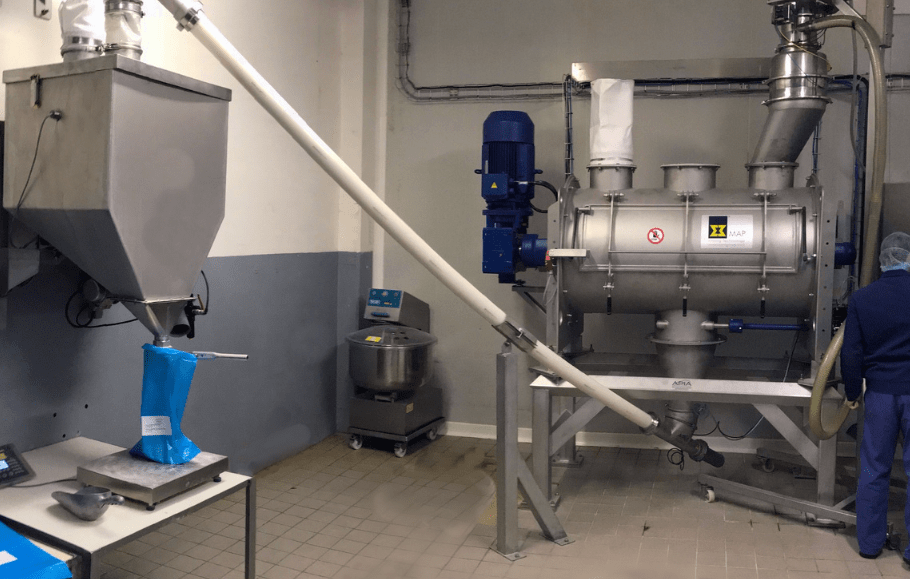

- Alimenter un Mélangeur de Poudres

- Alimenter un Tamiseur

- Alimenter une Cuve de dilution

- Vider un Big bag

- Vider des sacs

- Vider des silos

- Vider des trémies tampons

- Vider un mélangeur

- Reprendre sous un tamiseur

- Reprendre sous une vis

- Services

- Savoir-faire

- Blog

- Cas-Clients

- Contact

- Nos produits

Powder transfer, dosing and processing systems for the food industry

Apia Technologie is the expert in the flexible mechanical conveying system Transitube®. This method of handling dry products is offered in a wide range of food-grade certified equipment. We also design all peripheral devices for making safe and regulating your bulk powder flows.

What are your needs?

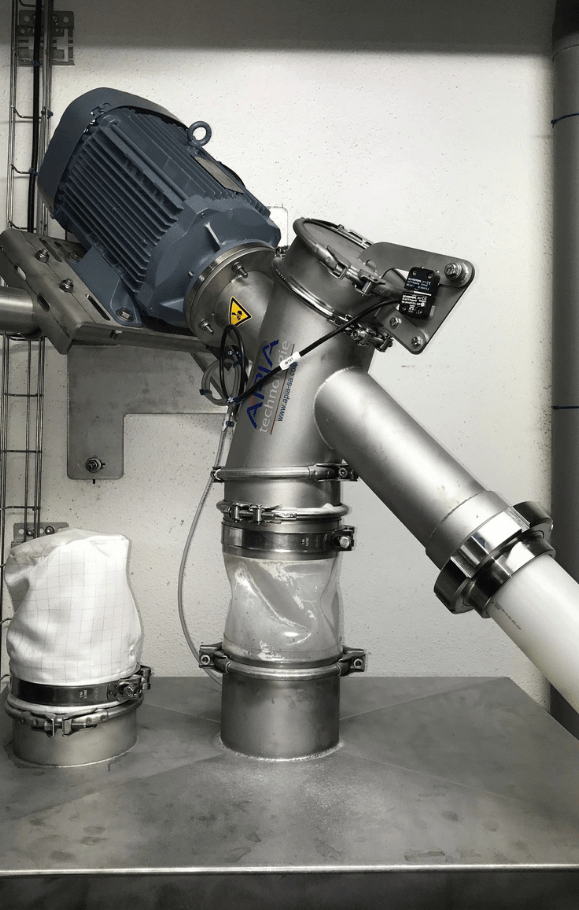

T11 transfer auger with de-bridger

Transferring non-free-flowing powders

T12 transfer auger with distributor

Transferring powders with fluctuating flow

T14 transfer auger

Transferring free-flowing powders

T51 dosing auger with de-bridger

Distributing non-free-flowing powders

T54 dosing auger

Distributing free-flowing powders

Hoppers

Preparing intermediate batches and stocks with or without weighing

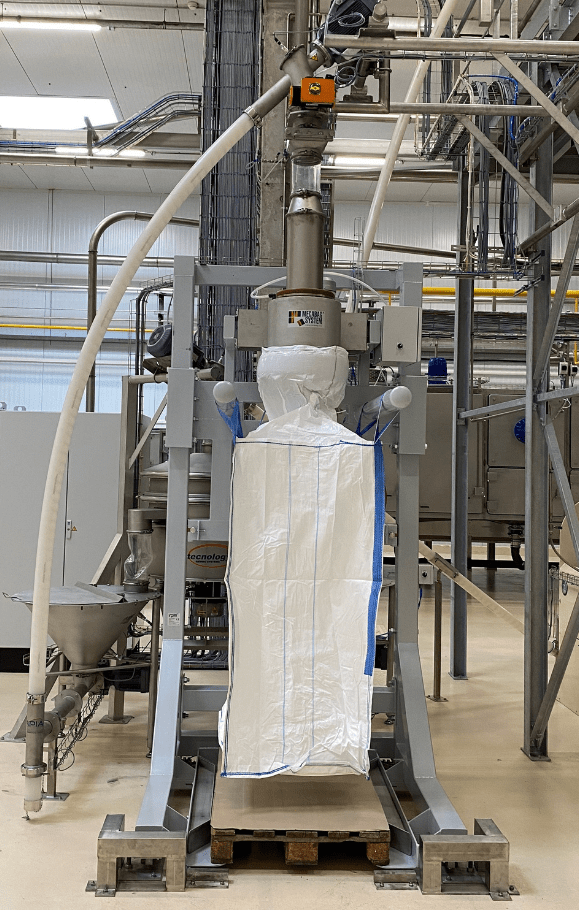

Type T, type V and type C big bag stations

Emptying big bags of powders having free to fluctuating flows

Type T and type V bag emptying hoppers

Emptying bags of free-flowing to non-free-flowing powders

Hood with filter or for remote filter

Emptying bags of volatile powders

Mobile bag emptier with mobile feeder transfer auger

Emptying bags of free-flowing powders

Contained weigher bagger

Automating powder weighing and bagging

Mobile weigher bagger

Automating powder weighing and bagging

Emptying and quick release of transfer augers

Facilitating and making safe the release of powder transfer equipment

Pipes and valves

Making up the gravity downpipe powder network

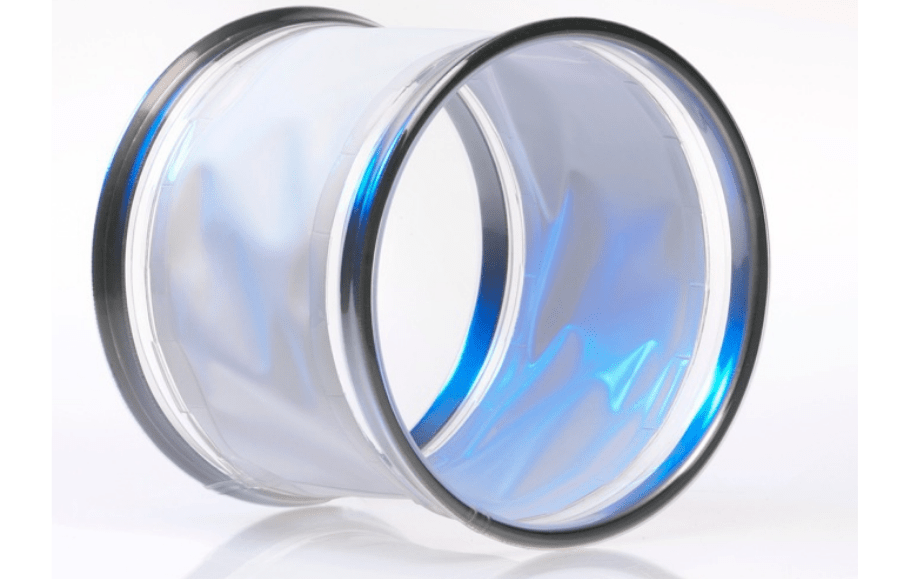

Connection sleeves

Securing the connections between the powder transfer network and the machines

Hygienic wall boots

Hygienic management of wall boots

Our Products

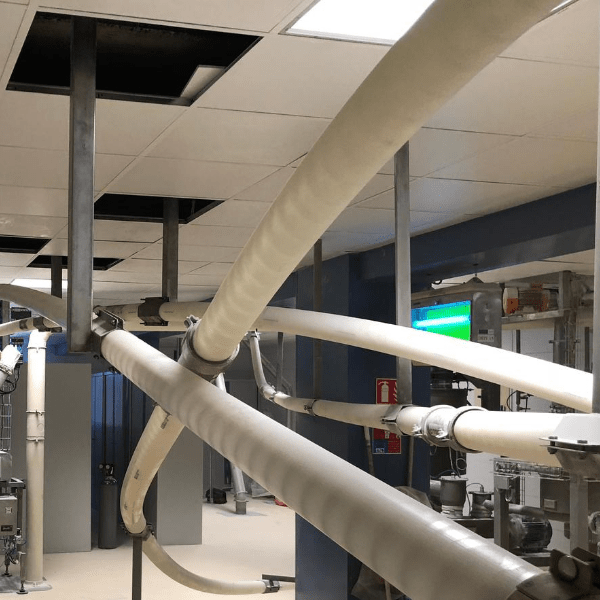

Flexible auger technology

5 reasons to choose Transitube® technology

Our technology is based on the Transitube® system which is made up of a reinforced stainless-steel coil rotating inside a conveyor tube. The coil rotation speed creates a ring of material which moves inside the tube in an air-free, dust-free environment, protected from external contamination and without being subject to particle segregation or reduction in particle size.

Closed and sealed systems

Limits dust accumulation in workshops and the risks of contamination by volatile materials.

For the food industry

Guarantees the compliance of our equipment with the current regulations applicable in your workshops, as well as the traceability of the materials used.

Regular and optimised throughput

Allows us to offer compact dosing systems with incomparable precision.

Product integrity

Transfers complex ingredients and powders with no particle segregation, separation or attrition.

Protects against harmful external factors

The product moves in an environment that is protected from humidity and contamination, including in outdoor conditions

Our services

We guarantee the performance of your installation

APIA Technologie undertakes not only to improve the safety and productivity of your food manufacturing workshops, but also to optimise your operators’ day-to-day working environment and the quality of your output. Our technical solutions are sound and logical, and designed with your needs in mind. Multiple direct and indirect savings: low operating costs, energy savings, supply optimisation, more

space, operators freed from repetitive tasks, fewer material and finished product losses, reduced downtime. Our technical and sales teams are in daily contact with the realities of your activity and with the requirements for food applications. Our installations are always scalable so as to minimise the cost of future extensions.

Trends

Connect with us,

by subscribing to our newsletter

My Form

Our processes

Our news

© Copyright 2026 APIA technologie