- Accueil

- Nos produits

- Ensemble de transfert T11

- Ensemble de transfert T12

- Ensemble de transfert T14

- Ensemble de distribution T51

- Ensemble de distribution T54

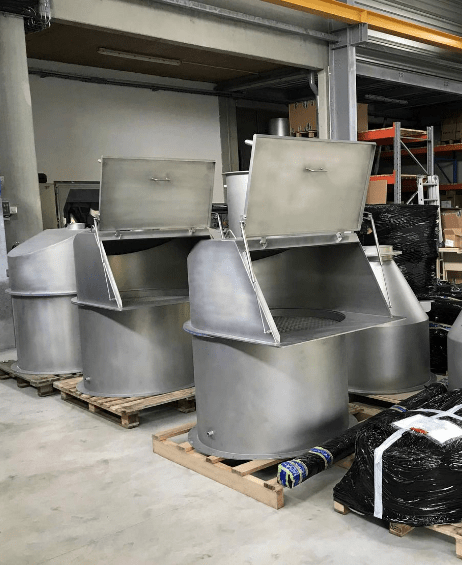

- Trémies pesées et trémies tampons

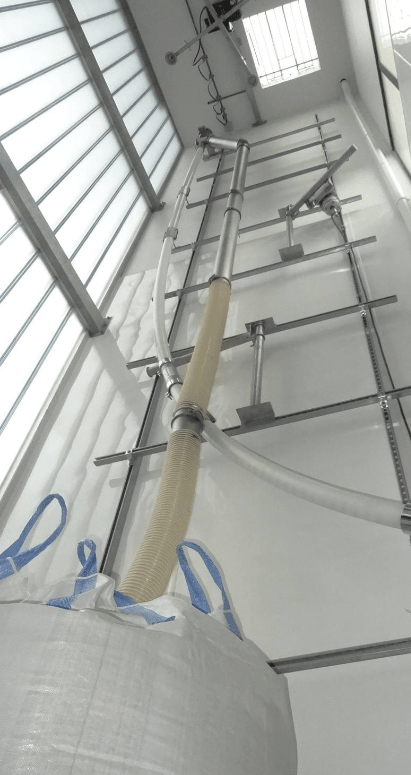

- Stations de vidange big bag

- Trémies vide-sacs

- Hottes de dépoussiérage

- Ensemble Mobile et Basculant (EMB)

- Ensacheuse Peseuse Confinée (EPC)

- Ensacheuse Peseuse Mobile (EPM)

- Options de vidange et démontage rapides

- Conduits et vannes

- Manchettes de connexion

- Passe Cloisons

- Nos Solutions

- Alimenter un Big Bag

- Alimenter une Ensacheuse

- Alimenter une Conditionneuse

- Alimenter des silos et trémies tampons

- Alimenter une Trémie pesée

- Alimenter un Doseur

- Alimenter un Mélangeur Poudres-Liquides

- Alimenter un Mélangeur de Poudres

- Alimenter un Tamiseur

- Alimenter une Cuve de dilution

- Vider un Big bag

- Vider des sacs

- Vider des silos

- Vider des trémies tampons

- Vider un mélangeur

- Reprendre sous un tamiseur

- Reprendre sous une vis

- Services

- Savoir-faire

- Blog

- Cas-Clients

- Contact

- Nos produits

Bespoke and Turnkey solutions

Our technical and sales teams take care of the engineering, manufacture, project management and monitoring of your installations. We deliver complete transfer and dosing lines designed in accordance with your needs.

Consulting and engineering

In constant contact with every agri-food sector, the APIA Technologie experts visit your plant in person in order to gain an understanding of your objectives and to work with you to develop the best implementation strategy.

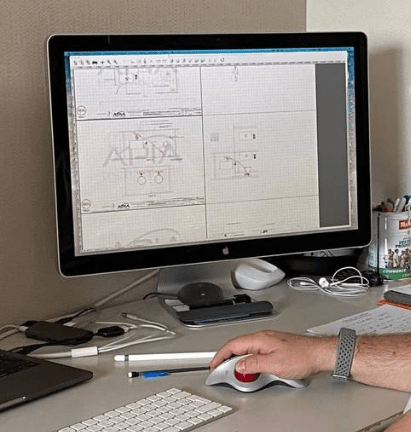

Layout studies

An in-depth understanding of your on-site operations and your objectives is paramount for the optimum end result. We work with you on-site to study the focuses for rationalisation of your powder circuit and to develop the best implementation strategy according to your expectations.

At this stage, samples of the ingredients requiring conveying are analysed in order to best identify behaviour and constraints.

Full-scale tests and provision of equipment

Food products are living products. Their behaviour in an industrial situation may differ from that of a single sample. Every powder requiring transfer or dosing has its own individual characteristics: it may be fragile and poses attrition concerns, it may be sensitive to particle segregation, or to temperature.

Do you want to check that the proposed solution will keep its promises? Or launch a pilot production run? Then our test laboratory is at your disposal. In our laboratory, we create a full-scale reproduction of the anticipated handling cycle under operating conditions that are as close as possible to reality.

These tests thus validate the correct configuration of the flexible mechanical transfer system as well as the desired performances. Do you want to test a solution at your own facilities? Apia Technologie also offers solutions for the provision of equipment.

Project management

You will enjoy the services of a dedicated project manager from the APIA Technologie design office. From technical design to the commissioning of the installation, he or she will be your sole contact.

Technical formalisation

Our technical engineers define the technical specifications and design the bespoke equipment A detailed implementation plan is developed. The functional analysis describes the product flows in precise detail as well as the operation of the automated systems.

Manufacture and build

The APIA Technologie technical team then supervises the manufacture and acceptance of the equipment. The project manager assembles the installation links and verifies their conformity.

With complete transparency, you will also enjoy the benefit of our network of peripheral equipment manufacturer partners. In its capacity as project manager, APIA guarantees the correct operation and performance of the line in its entirety.

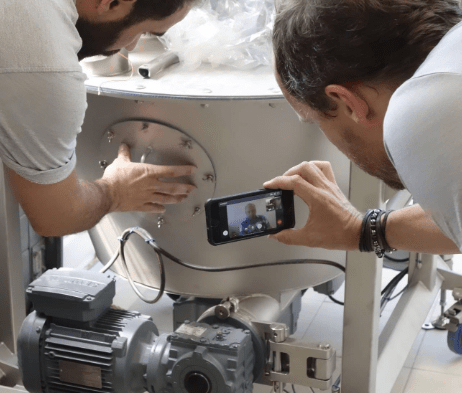

Assembly and commissioning

Finally, your dedicated project manager coordinates the delivery and on-site assembly of your turnkey installation, in collaboration with you and your local partners.

He or she visits your factory in person to oversee the commissioning of the equipment, to accept the performance of your new powder transfer installation and to train your operators.

Long-term commitment

If correctly used and well maintained, the flexible mechanical transfer technology will prove extremely robust, reliable and cost-effective. In addition to monitoring the equipment, we also support the scaling of your production facilities over the long-term.

After-sales service and maintenance

APIA Technologie installations are guaranteed for 1 year. We also offer bespoke preventive maintenance contracts.

Furthermore, our electronic archives of every project since 1992 constitute a valuable memory of our installations. They allow maintenance and optimisation of existing systems and processes at the lowest possible cost.

Our spare parts service is at your disposal and can supply you with certified spare parts within 48 hours.

Audits and training

The safety and quality of your products, evolving standards and technologies, the mass production of new products… all key factors that spur you to develop your existing process.

APIA Technologie specialists are on hand to carry out standards compliance audits (food approval, ATEX, safety of persons, etc.) or production line optimisation audits. We also train your teams in good practices that promote the longevity of your transfer and dosing equipment.

Online support

Your production is optimised to meet your customers’ expectations, particularly in terms of delivery deadlines. Production stoppages are costly and adversely affect your service.

For this reason, our online support is at your disposal to offer you prompt assistance.

Our values

Long-term support, innovation and eco-responsibility

APIA Technologie has been a recognised innovating French company for almost 30 years. We work for and with our customers in the food industry. We guarantee performances and results. Our solutions are the product of our innovative spirit and our experience in the food industry. Every one of our employees ascribes to the values of integrity, knowledge transfer and respect for all the actors involved in your project. Geographical proximity and customer contact are always given high priority.

We select providers who are geographically close to our customers’ facilities. Our company may be based in Brittany, but our reach is international. We are dedicated to developing added value across our territory by using the services of local partners wherever possible. Apia Technologie also devotes particular care to the confidentiality of data exchanged with its customers. Very strict computer security and data destruction protocols are applied every day.

Trends

Connect with us,

by subscribing to our newsletter

My Form

Our processes

Our news

© Copyright 2026 APIA technologie