- Accueil

- Nos produits

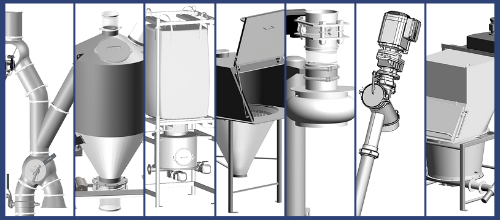

- Ensemble de transfert T11

- Ensemble de transfert T12

- Ensemble de transfert T14

- Ensemble de distribution T51

- Ensemble de distribution T54

- Trémies pesées et trémies tampons

- Stations de vidange big bag

- Trémies vide-sacs

- Hottes de dépoussiérage

- Ensemble Mobile et Basculant (EMB)

- Ensacheuse Peseuse Confinée (EPC)

- Ensacheuse Peseuse Mobile (EPM)

- Options de vidange et démontage rapides

- Conduits et vannes

- Manchettes de connexion

- Passe Cloisons

- Nos Solutions

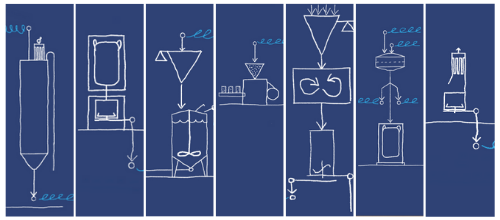

- Alimenter un Big Bag

- Alimenter une Ensacheuse

- Alimenter une Conditionneuse

- Alimenter des silos et trémies tampons

- Alimenter une Trémie pesée

- Alimenter un Doseur

- Alimenter un Mélangeur Poudres-Liquides

- Alimenter un Mélangeur de Poudres

- Alimenter un Tamiseur

- Alimenter une Cuve de dilution

- Vider un Big bag

- Vider des sacs

- Vider des silos

- Vider des trémies tampons

- Vider un mélangeur

- Reprendre sous un tamiseur

- Reprendre sous une vis

- Services

- Savoir-faire

- Blog

- Cas-Clients

- Contact

- Nos produits

Powder experts in the agri-food industry

For almost 30 years, we have been making innovations in the systems for the preparation and use of your bulk solid raw materials. Our activity is entirely dedicated to the agri-food industry and we are in constant touch with the reality of your business.

Our field of play

Do just one thing and do it well. APIA Technologie is the expert in powder processes for the food industry, and the flexible mechanical feeder specialist. This gives us unique know-how in this field.

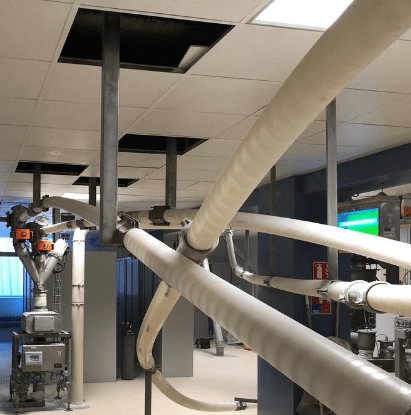

Transfer and dosing by flexible mechanical auger conveyor

The principle behind the Transitube® flexible auger conveyor is a versatile, simple, cost-effective, environmentally responsible and hygienic transfer technology. Powders and ingredients are conveyed at atmospheric pressure, protected from the air and external sources of contamination, without being subject to particle segregation or reduction in particle size. APIA Technologie constantly develops and improves its conveying and dosing technology.

Exclusively for the food industry

Our sales personnel and project managers are experts in all food processing sectors: biscuit products, bakery, confectionery, dairy products, ready meals, drinks, flavourings and many more besides. They are familiar with the standards applicable to them, their vocabulary and uses, and also with the issues specific to your business. They have interfaced hundreds of machines with our powder transfer networks: mixers, dispersers, syrupers, grinders, kneaders, sprinklers, sieves, dilution tanks, extruders, packaging machines, conches, mogul lines, churns.

Focus on the process end-to-end, from storage through to the finished product

Over and above the simple conveying of food powders, APIA Technologie offers expert competence at every stage in the flow of dry products. Choice of type of storage, workshop organisation, dosing methods, continuous production or batch preparation. Our knowledge base is unique as it is built on thousands of projects delivered exclusively in food environments. We also have a library of hundreds of certified powders.

Food expertise

Our manufactured products fall within the scope of various standards and directives. They are designed, first, to protect the health and safety of workers and, second, to meet the requirements of compatibility with foodstuffs.

Hygienic design

A corporate member of the EHEDG, we never compromise on the food-grade quality of our equipment. All our installations meet all the hygiene standards laid down by the inspection bodies, allowing you to certify your food processing workshop.

APIA Technologie incorporates the principles of hygienic design (disassembly, cleanability and limitation of product entrapment areas) into all its solutions. All materials and components used are guaranteed for food usage. Compliant with EC Regulation 1935/2004, they undergo an in-depth incoming inspection upon arrival. We are able to provide you with the food contact certificate for all our equipment.

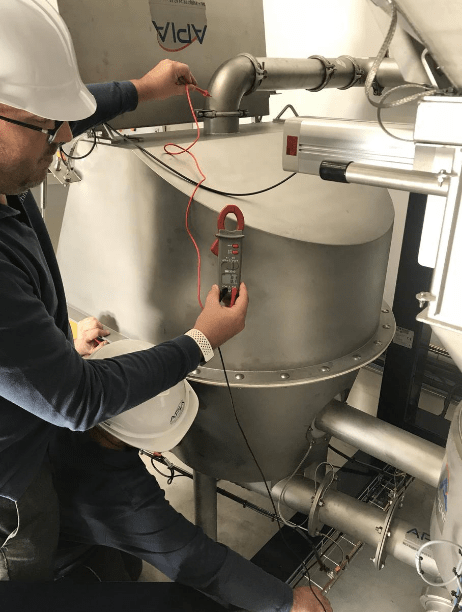

ATEX certification

The intention of the ATEX Directive is to clear equipment for use in explosive atmospheres without uncontrolled risks. Within this often poorly understood regulatory framework, APIA Technologie provides its ATEX expertise and offers the only transfer solution on the market to be certified by an external body. The marketing authorisation for the transfer and dosing equipment in the Transitube® range for Explosive Atmospheres goes back to 2007.

Our equipment is classified as Category 1 (Zone 20 interior, the most stringent). This certification is backed by a strict quality assurance system, with a twice-yearly inspection by the notified body, INERIS. Finally, the APIA Technologie teams receive regular training on this subject and have had an in-company ATEX coordinator at their disposal for consultation since 2007.

Our method

Your project from A to Z

Consulting and engineering

Meeting your needs and addressing your challenges

- Objectives, site audit, study of drawings

- Analysis of powders, laboratory testing, full-scale tests

- Process recommendation, diagram, budget

Project management

Delivering a turnkey installation

- Design, layout, functional analysis

- Manufacture and build

- Assembly, commissioning

Long-term commitment

Optimising your powder process

- Guarantee, technical documentation, annual monitoring

- After-sales service, training, spare parts

- Audit, recommendations

Our solutions and products

APIA Technologie relies on powder handling and processing solutions that are both simple and efficient. Our installations are robust and scalable. Their operation is cost-effective and eco-responsible.

For efficient production lines

Apia Technologie is the expert in Transitube® technology. All our equipment is designed for bespoke integration into your existing plant.

For optimised and profitable processes

Our series of recommendations on the organisation of your food production is informed by thousands of installations supplied and installed by APIA Technologie.

Scope of intervention

APIA Technologie on the international stage

A pioneer in the development of food powder transfer, APIA Technologie was naturally first established in Brittany, home to the leading food industry operators, but quickly established a presence across France.

Starting in 1998, the company expanded its food-grade powder transfer activity into Europe. Today, APIA Technologie installations are in use all over the world, including on the continents of Africa and America.

Trends

Connect with us,

by subscribing to our newsletter

My Form

Our processes

Our news

© Copyright 2025 APIA technologie